Get 30 days FREE. No credit card required.

500,000+ Assets Tracked Across Sites Worldwide

Every Blind Spot in the Field Costs You More.

Lost Assets in Harsh, Remote Environments

Tools go missing across sites with no visibility or tracking.

Unplanned Downtime Hurts Production

Missed maintenance leads to costly delays and asset failure.

Manual Compliance Tracking

Paper logs slow inspections and increase audit risks.

No Usage Accountability

Assets switch hands with no tracking or responsibility.

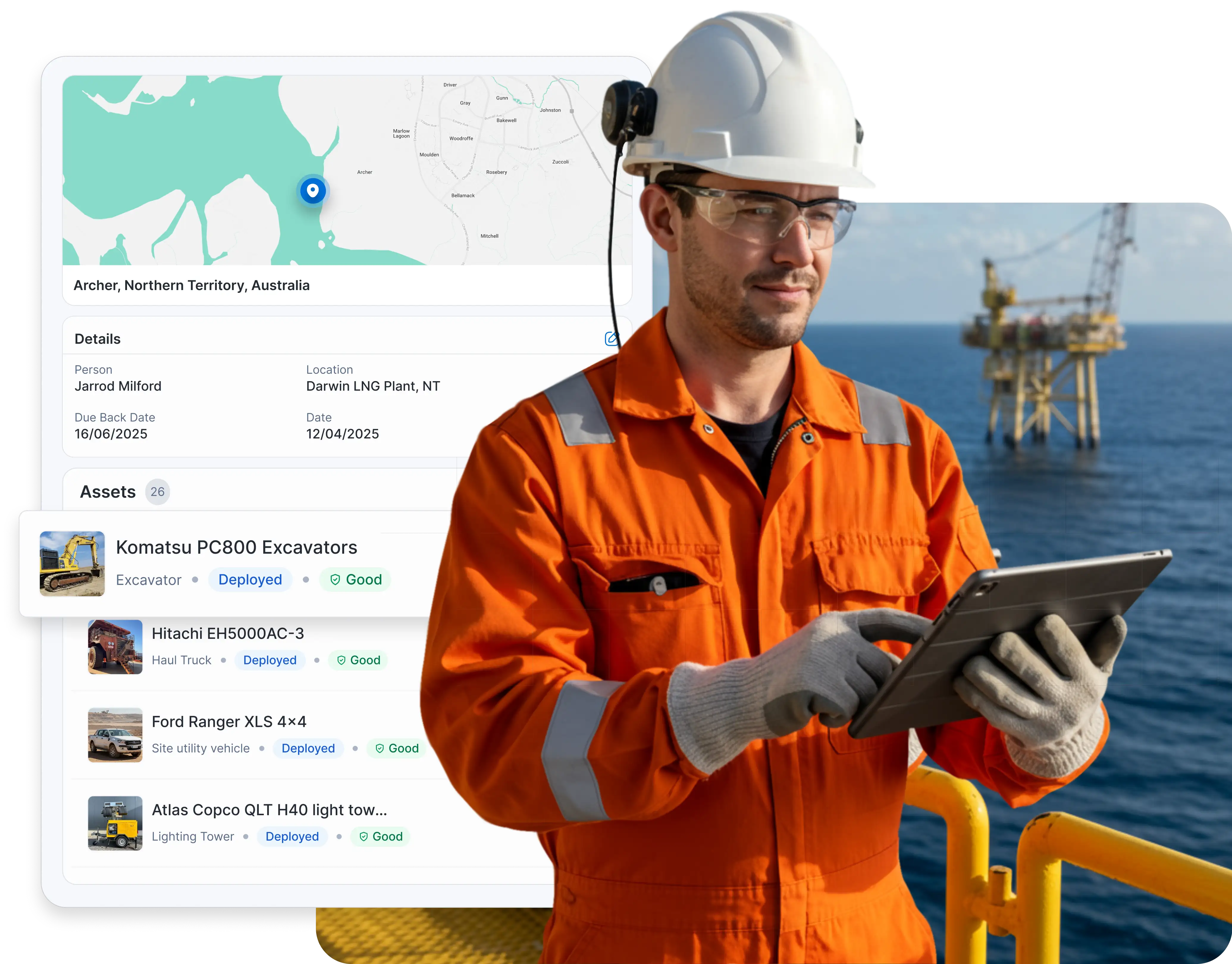

MapTrack Keeps You Running — Safer, Smarter, and Fully Compliant

Track Tools in Real Time

GPS, QR, or Bluetooth shows exact asset locations instantly.

Mobile Offline Inspections

Log faults and checks without needing internet access.

Assign Assets to Crews

Tools are clearly linked to teams, jobs, or locations.

Automated Service Records

Every inspection is logged, audit-ready, and easy to find.

How it works

Here's how MapTrack helps your team go faster

Step 1

Tag Assets

Add your tools, equipment, and vehicles into MapTrack. Tag each item using QR codes, GPS devices, or Bluetooth trackers for instant identification and future tracking.

Step 2

Track & Maintain

Track asset location in real-time, schedule automatic maintenance, and ensure compliance with safety checks, inspections, and calibration reminders.

Step 3

Analyse & Improve

Generate reports, monitor usage trends, and identify underused or high-risk assets. MapTrack helps you reduce downtime, cut costs, and boost operational efficiency.

Happy MapTrack customers

“Before MapTrack, managing tools across multiple pipeline sites was time-consuming and inconsistent. Now every asset is tagged, assigned, and tracked, which has improved both efficiency and accountability. Maintenance reminders help us avoid breakdowns, and our crews always know where equipment is. It’s a simple solution that’s made a big impact on daily operations.”

“We operate offshore where internet is unreliable and downtime is expensive. MapTrack’s offline mode, quick check-in/out system, and fault reporting have streamlined how we manage tools and inspections. It’s improved compliance tracking and saved hours each week. Our team relies on it daily — it’s become an essential part of our workflow.”